With Ecotherm this heat is recovered and reused.

Heat harvesting

The Ecotherm system uses refrigeration plant to provide both hot water for heating and chilled water for air-conditioning simultaneously. This water is piped around the building to air handling units via a four pipe network. The heat which is extracted from the chilled water along with the electrical energy used to drive the refrigeration compressor is transferred to the heating water. In this way energy is harvested from the warmer parts of the building and transferred to the colder parts of the building requiring heating.

The Ecotherm system uses refrigeration plant to provide both hot water for heating and chilled water for air-conditioning simultaneously. This water is piped around the building to air handling units via a four pipe network. The heat which is extracted from the chilled water along with the electrical energy used to drive the refrigeration compressor is transferred to the heating water. In this way energy is harvested from the warmer parts of the building and transferred to the colder parts of the building requiring heating.

Heat absorbtion

When more heating is required than can be harvested from the building, the Ecotherm system absorbs heat from the outside air using a two stage evaporator coil. Up to 4 kW of heat can be gathered in this way for each 1 kW of electrical energy expended. This coil is fitted with embedded electric defrost elements. The coil staging and defrost elements are managed to ensure that ice does not build up on the coil and impede heat absorbtion. Unlike other systems there is no reversing of the refrigeration cycle involved in the defrost process. Reversing the cycle essentially removes heat from the occupied spaces to melt ice on the outdoor coil which can cause cold drafts. Ecotherm however, is able to provide continuous heating.

When more heating is required than can be harvested from the building, the Ecotherm system absorbs heat from the outside air using a two stage evaporator coil. Up to 4 kW of heat can be gathered in this way for each 1 kW of electrical energy expended. This coil is fitted with embedded electric defrost elements. The coil staging and defrost elements are managed to ensure that ice does not build up on the coil and impede heat absorbtion. Unlike other systems there is no reversing of the refrigeration cycle involved in the defrost process. Reversing the cycle essentially removes heat from the occupied spaces to melt ice on the outdoor coil which can cause cold drafts. Ecotherm however, is able to provide continuous heating. Heat rejection

When excess heat is being generated in the building this heat is rejected to the outside air using a dry cooling coil. Heating water is passed through this coil and fans are used to draw air through the coil and dissipate the excess heat.

When excess heat is being generated in the building this heat is rejected to the outside air using a dry cooling coil. Heating water is passed through this coil and fans are used to draw air through the coil and dissipate the excess heat.

Heat recovery

The building is supplied with a fixed quantity of fresh air to ensure that the occupants remain healthy. An equal quantity of stale air is removed from the building via the toilets, photocopying rooms and other general points. As this air is extracted from the building it passes over a cooling coil which recovers a significant amount of energy from it. This energy is then recycled for heating the building or ventilation air stream again. The energy recovered in this way is sufficient to heat between 50 & 100% of the ventilation air stream depending on the outdoor air temperature.

The building is supplied with a fixed quantity of fresh air to ensure that the occupants remain healthy. An equal quantity of stale air is removed from the building via the toilets, photocopying rooms and other general points. As this air is extracted from the building it passes over a cooling coil which recovers a significant amount of energy from it. This energy is then recycled for heating the building or ventilation air stream again. The energy recovered in this way is sufficient to heat between 50 & 100% of the ventilation air stream depending on the outdoor air temperature.

Air handling units

The Ecotherm system utilises fan coil units with a single coil to service each zone of the building. Each fan coil unit is fitted with a changeover valve to enable selection of either heating or cooling water. A modulating valve for each service is used to control the amount of water flow through each fan coil unit according to demand. Local wall mounted sensors indicate room temperature, provide a night over-ride button and allow for local setpoint adjustment. The simple user interface is considered very important to the success and acceptance of the system.

Building management system

The Ecotherm plant is controlled by a digital building management system. This allows the operation of the plant to be controlled with a software program which provides enormous flexibility in the control of the plant and enables easy tuning and optimising of the system. Digital control enables a large range of variables to be monitored and used in the management of the system. The system can be remotely accessed via a modem.

The Ecotherm plant is controlled by a digital building management system. This allows the operation of the plant to be controlled with a software program which provides enormous flexibility in the control of the plant and enables easy tuning and optimising of the system. Digital control enables a large range of variables to be monitored and used in the management of the system. The system can be remotely accessed via a modem.

Occupancy Sensors

Sensors are used to determine when partially utilized rooms are occupied and adjust the lighting and comfort levels accordingly. These sensors save lighting energy, heating and cooling energy, extend lamp or tube life, and can also be used as security sensors during unoccupied periods.

Sensors are used to determine when partially utilized rooms are occupied and adjust the lighting and comfort levels accordingly. These sensors save lighting energy, heating and cooling energy, extend lamp or tube life, and can also be used as security sensors during unoccupied periods.

Environment

Ecotherm allows year round comfort levels to be achieved in a building in a most environmentally friendly way. There is no carbon dioxide generated by burning fossil fuels for heating. Energy is used in the most efficient way. Electrical energy used initially for running lights or computers is recycled for heating purposes when required. Water is used as the main heat transfer medium and there is only a small amount of HCFC refrigerant used in the refrigeration plant. This refrigerant is a small fraction of what would be required for a system using refrigerant as the principle heat transfer medium. Ecotherm is an economical and ecologically sound approach to providing thermal comfort in buildings and promises to become the benchmark against which other systems are measured in the future.

Ecotherm allows year round comfort levels to be achieved in a building in a most environmentally friendly way. There is no carbon dioxide generated by burning fossil fuels for heating. Energy is used in the most efficient way. Electrical energy used initially for running lights or computers is recycled for heating purposes when required. Water is used as the main heat transfer medium and there is only a small amount of HCFC refrigerant used in the refrigeration plant. This refrigerant is a small fraction of what would be required for a system using refrigerant as the principle heat transfer medium. Ecotherm is an economical and ecologically sound approach to providing thermal comfort in buildings and promises to become the benchmark against which other systems are measured in the future.ECOTHERM – A TECHNICAL OVERVIEW

1. ECOTHERM FUNDAMENTALS

- Ecotherm is an integrated heating, ventilating and air-conditioning system for medium to large commercial or institutional buildings.

- Ecotherm is extremely energy efficient because it makes optimum use of the energy available in a building by harvesting spare or waste heat from within the building including solar energy absorbed by the building the sensible and latent heat emitted by the occupants all or part of the energy used to heat the ventilation air stream (depending on the ambient air temperature).

- This energy is collected and concentrated to generate heat at useful temperatures which can then be applied to areas of the building requiring heating.

- A basic premise of the Ecotherm concept is that for a significant part of the year the heating and cooling demands of a building will overlap. Energy can therefore be collected from the areas of the building being cooled and used to heat areas requiring heating.

- This premise has been proven correct in practice at the 2000 m2 office building in Invercargill where a prototype plant has been installed and operating satisfactorily for five years.

- This overlap of cooling and heating demand and the potential to transfer energy from one part of the building to another has never been fully exploited until now.

- Traditionally a cooling plant has been used to provide chilled water and a heating plant used to supply heating water. The heat extracted from the building by the cooling plant is normally just rejected to the environment using a dry cooler or a cooling tower.

- This approach has been due in part to a mind set that heating water needs to be 70–80°C.

- Ecotherm heats a building with 30°C - 40°C water.

- Heating and air-conditioning systems are often designed to meet peak load conditions with little consideration being given to performance and efficiency at part load conditions.

- Ecotherm has been designed to work efficiently at all load conditions by using multi-staged compressors and multi-staged heat absorption and rejection plant.

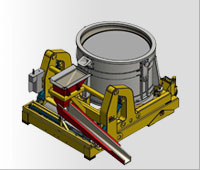

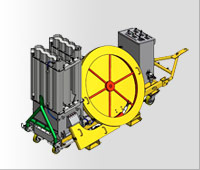

2. ENERGY PLANT

- The Ecotherm energy plant utilizes a refrigeration compressor to transfer heat from a chilled water circuit to a heating water circuit.

- The chilled water is pumped around the building and made available to the air handling plant. Any item of air handling plant can call on this chilled water to effect cooling in the building.

- Heating water is provided to the building in the same way.

- When the heating load exceeds the cooling load the Ecotherm plant can top up the supply of heat to the building by extracting heat from the outdoor air using an evaporator coil or coils.

- The outdoor evaporator coil/s is/are connected in parallel with the chilled water evaporator.

- Solenoid valves are used to control liquid refrigerant flow to the evaporators.

- Electric elements are embedded in the outdoor evaporator to enable the coils to be de-iced.

- A control valve is used to control the refrigerant suction pressure in the chilled water heat exchanger to prevent the chilled water from freezing while allowing lower suction temperatures to be achieved for extracting heat from cold outdoor air.

- The Ecotherm plant uses a dry cooler and the extract air heat recovery coil to reject heat to the environment when the building cooling load exceeds the heating load.

- The Ecotherm plant uses modulating bypass valves on both the cooling and heating circuits to ensure adequate water flowrates through the evaporator and condensing coils.

- These valves are also used to maintain constant system pressures.

3. AIR HANDLING PLANT

- Air handling plant used on four pipe systems such as this usually has either two separate coils for heating and cooling or a dual circuit coil.

- Ecotherm air handling plant is fitted with only one coil.

- This coil is used for both heating and cooling thus reducing the cost of the air handling units and reducing the fan energy required.

- A changeover valve is used to direct either chilled water or heating water to the coil depending on demand.

- The use of water as a heat transfer medium enables fully modulating heating and cooling valves to be used thus allowing more precise control of room temperatures to be achieved.

4. WATER RETICULATION

- The control valves on the air handlers are two port configuration compared with the normal three port arrangement.

- This allows the water reticulation network to be designed with full diversity factors i.e. if water is not required by one air handler it is available to others on the circuit.

- The pumps and pipework can be then be sized to deliver enough water to satisfy the total instantaneous load on the building as a whole rather than the sum of the peak loads for each air handler.

- This reduces the size and capital cost of the piping network and the size, capital and running cost of the pumps.

- The bypass valves in the plant room modulate to maintain constant system pressures thus ensuring each air handler is provided with enough water.

- The bypass valves on the end of each supply pipe open at preset pressures to ensure that water circulates through the supply pipes at times of low demand.

- This ensures water supply temperatures are held constant throughout the building even at times of low demand i.e. the water can not stay stationary in the pipes and cool down or heat up.

- Where possible reverse return piping networks are used to provide more even pressure differentials for each air handler.

5. CONTROL

- The Ecotherm system is controlled with a Direct Digital control System (DDS).

- Each air handler is fitted with a Terminal Equipment Controller (TEC).

- Each TEC is connected to a (Local Area Network) LAN.

- The LAN is driven by a computer in the plant room.

- The operating instructions for the Ecotherm plant and system are contained in a custom written program installed on the computer.

- The controller is accessible via modem allowing remote adjustments, fault finding or program adjustments.

6. OVERVIEW OF SYSTEM ADVANTAGES

The advantages of the Ecotherm concept over alternative forms of heating and cooling are as follows:

- One refrigeration plant is used to supply both cooling and heating water for a building simultaneously.

- A refrigerant/water evaporator is used in parallel with a refrigerant/air evaporator on the same compressor to effect both heat recovery and heat absorption from outside air simultaneously.

- Low temperature hot water (30°C - 40°C) is used for heating the building thus reducing heat loss from pipework.

- Single coil air handlers are used in conjunction with changeover valves to effect both heating and cooling in a building.

- One air handler is used for both extracting energy from the exhaust air and rejecting heat in the cooling season.